- #Typical common rail piezo injector. verification

- #Typical common rail piezo injector. plus

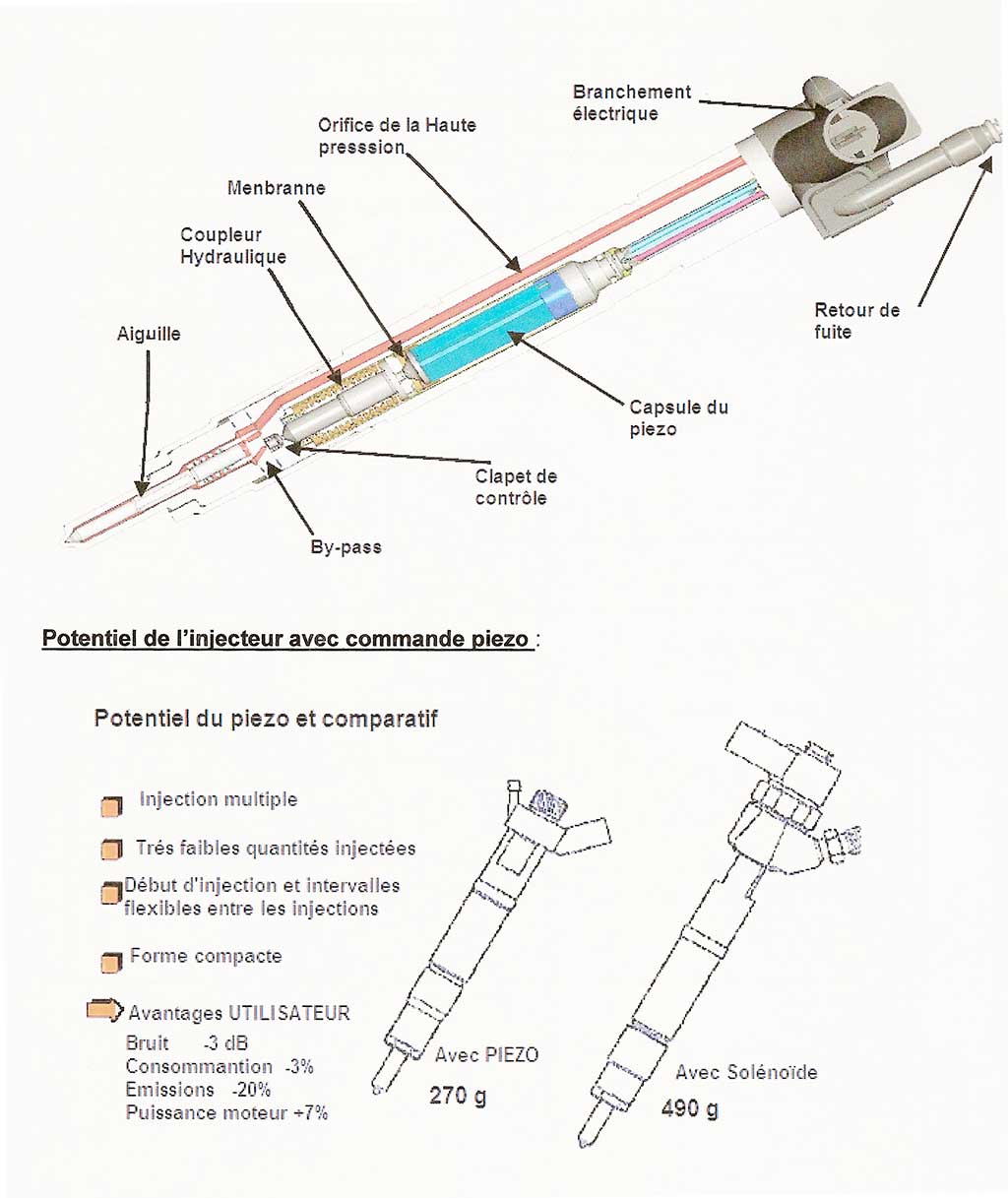

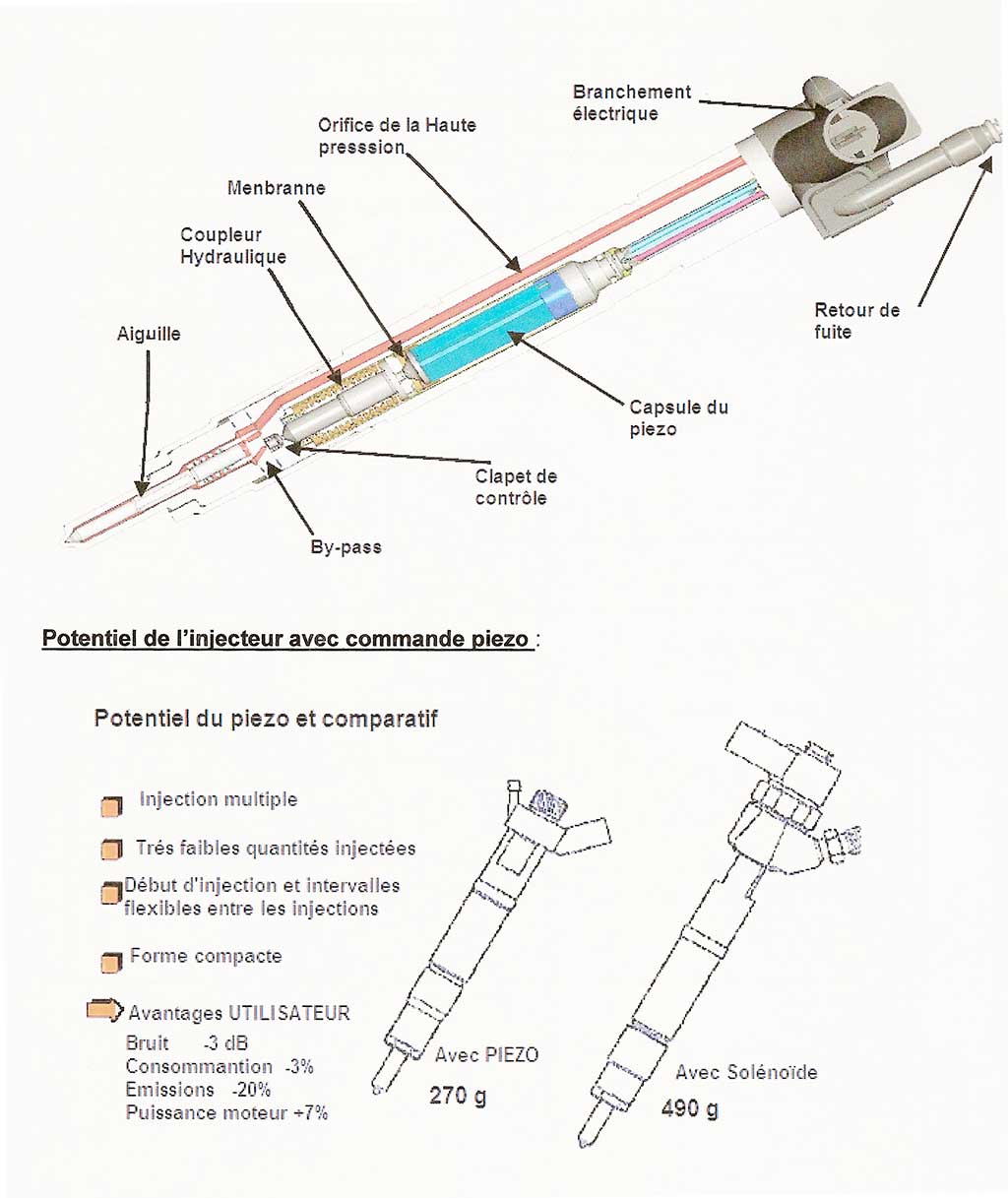

The Continental injector has hundreds of little piezo slices stacked on top of each other so that the combined expansion increases the total motion. That two-hundred-thousandths of an inch is not nearly enough to move an injector’s pintle, which is the part that seals the nozzle and must open to inject fuel.

A slice of piezo material two-hundredths of an inch thick expands only about 0.00002 inch when it gets hit with roughly 140 volts of electricity.

One reason is that the expansion of the piezo crystals is minuscule. Making these devices work, however, isn’t easy. Bosch, Continental, and Delphi, among others, have harnessed this peculiar property of expanding piezo material-rather than the usual electromagnet-to open the fuel-injector nozzle and precisely spray fuel into both gasoline and diesel engines. Take, for example, the precise metering necessary for modern-day fuel delivery. There are numerous places in a car where piezoelectric expansion can come in handy. But the process is also reversible, in that these same materials expand slightly when electricity is applied to them. There’s even a word for it: “piezoelectric,” which describes electricity resulting from pressure.

Determining the influence of various sensors on the different actuators.If you’ve ever seen the sparks created by someone munching Wint-O-Green Life Savers in a darkened room, you’ll have witnessed this phenomenon: Certain crystalline materials, such as sugar, produce minute amounts of electricity when you squeeze them. #Typical common rail piezo injector. verification

Verification of the actuators - with multimeter and oscilloscope: supply voltage, control signals, component testing. Verification of the sensors - with multimeter and oscilloscope: power supply, signals, component testing. #Typical common rail piezo injector. plus

Verification of the power supply side plus and minus side.Making screen-shots of all signals, all control voltages and the CAN data-bus with a digital oscilloscope and storing them for customer-specific documentations.Measuring and assessing sensor signals and actuator control voltages, recording CAN-bus signals with the oscilloscope and assessing signal levels.Using common OBD diagnostic tools for the workshop.

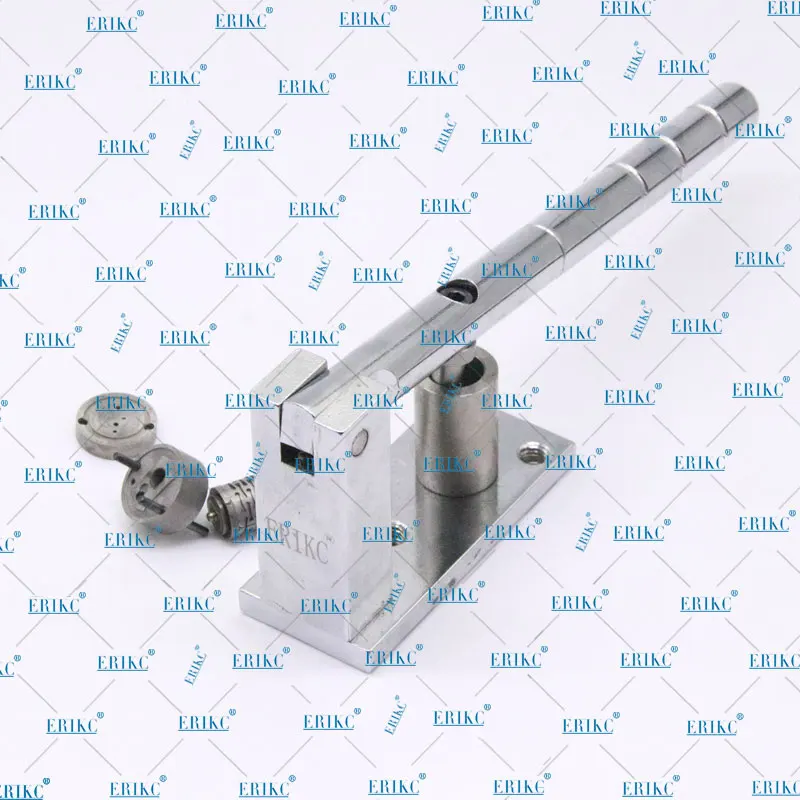

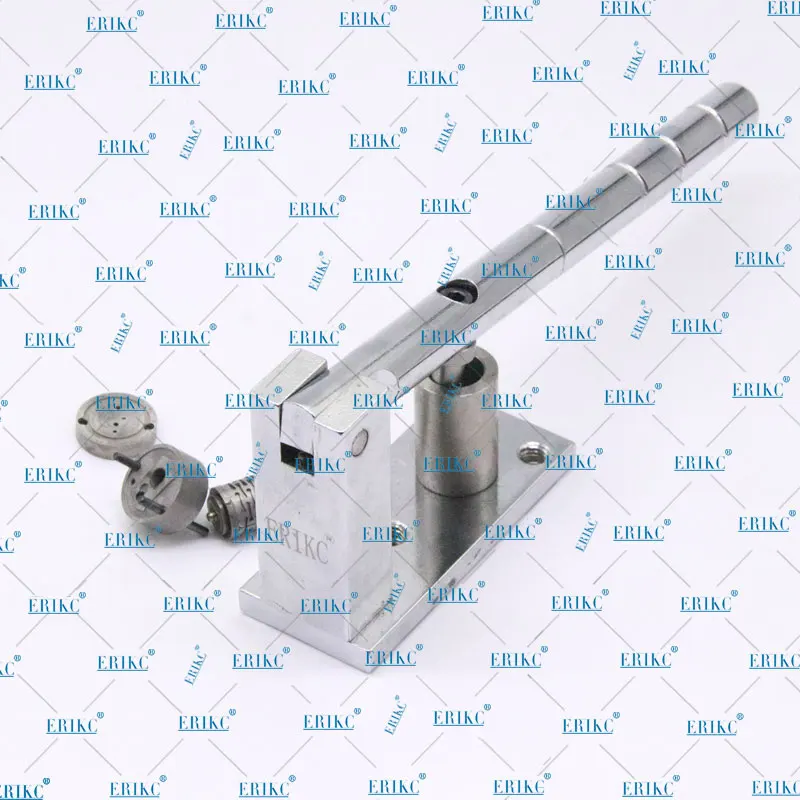

Determining reference values depending on operating situation. Working with original schematics and specify problem-oriented connector pins on components and control unit. TDI injection technology: Name components of the entire common-rail engine management and explain the interaction of the components. Compact device build, mobile, for lab and workshop practice. Connection for student circuit diagram measuring desks. Arrangement in the IPO principle: input - processing - output. Measuring of all relevant parts and components in the central circuit diagram measuring field. Original parts, TDI piezo injection technology, Original injection pressures. This means the system can be put into operation immediately upon setup. The required power supply, wiring and component configuration are already integrated into the system and preset, ready for operation. All original parts and required components are clearly arranged in the IPO-principle on the color printed front panel. With this teaching and training rig with common rail piezo injection technology all functions and processes, errors and measuring values can be demonstrated and examined without emissions as they are in the original engine. Diesel Injection System - TDI (VW) - proline

Determining reference values depending on operating situation. Working with original schematics and specify problem-oriented connector pins on components and control unit. TDI injection technology: Name components of the entire common-rail engine management and explain the interaction of the components. Compact device build, mobile, for lab and workshop practice. Connection for student circuit diagram measuring desks. Arrangement in the IPO principle: input - processing - output. Measuring of all relevant parts and components in the central circuit diagram measuring field. Original parts, TDI piezo injection technology, Original injection pressures. This means the system can be put into operation immediately upon setup. The required power supply, wiring and component configuration are already integrated into the system and preset, ready for operation. All original parts and required components are clearly arranged in the IPO-principle on the color printed front panel. With this teaching and training rig with common rail piezo injection technology all functions and processes, errors and measuring values can be demonstrated and examined without emissions as they are in the original engine. Diesel Injection System - TDI (VW) - proline

0 kommentar(er)

0 kommentar(er)